-

Achieved a switching power supply power density of 2.75 ㎤/W through use of PWSB. This contributed to product downsizing.

- Switching power supplies

- FA equipment

- Industrial robots

- Downsizing

- Decreasing weight

Solution and proposal content

The customer wanted to “reduce the size of the power supply in order to downsize the product”.

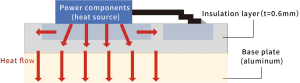

In order to downsize the power supply, it was necessary to efficiently reduce the heat generated from the power supply, but if a large heat sink and cooling fans were added for cooling, it would increase the size of the power supply. As a solution we switched the cooling method to using PST’s proprietary PWSB product to carry out cooling by conducting heat to the device’s metal case. This allowed us to achieve a power density of 2.75 ㎤/W which made it possible to downsize the switching power supply.

*Power Solution Board (PWSB)

*Product information pages

-

Achieved a switching power supply input voltage range of 3 phase 440 to 480 V through innovative circuit architecture.

- Switching power supplies

- FA equipment

- Industrial robots

- Special specifications

Solution and proposal content

The customer was faced with the issue that “the addition of a transformer in order to handle high voltage would increase both product size and cost”.

The customer was using a step down transformer because there were not many parts which could handle high voltage. As a solution, we used an innovative circuit architecture composed of the available components to achieve compatibility with a switching power supply input voltage range of 3 phase 400 V.

*Product information pages